- The smallest of holes in a pipe can cause lots of wasted water which also means money wasted down the drain!

- Watch how an experienced Perth based Plumbdog Plumber finds and fixes burst water pipes.

- He sniffs out the problem on this property before finishing his coffee.

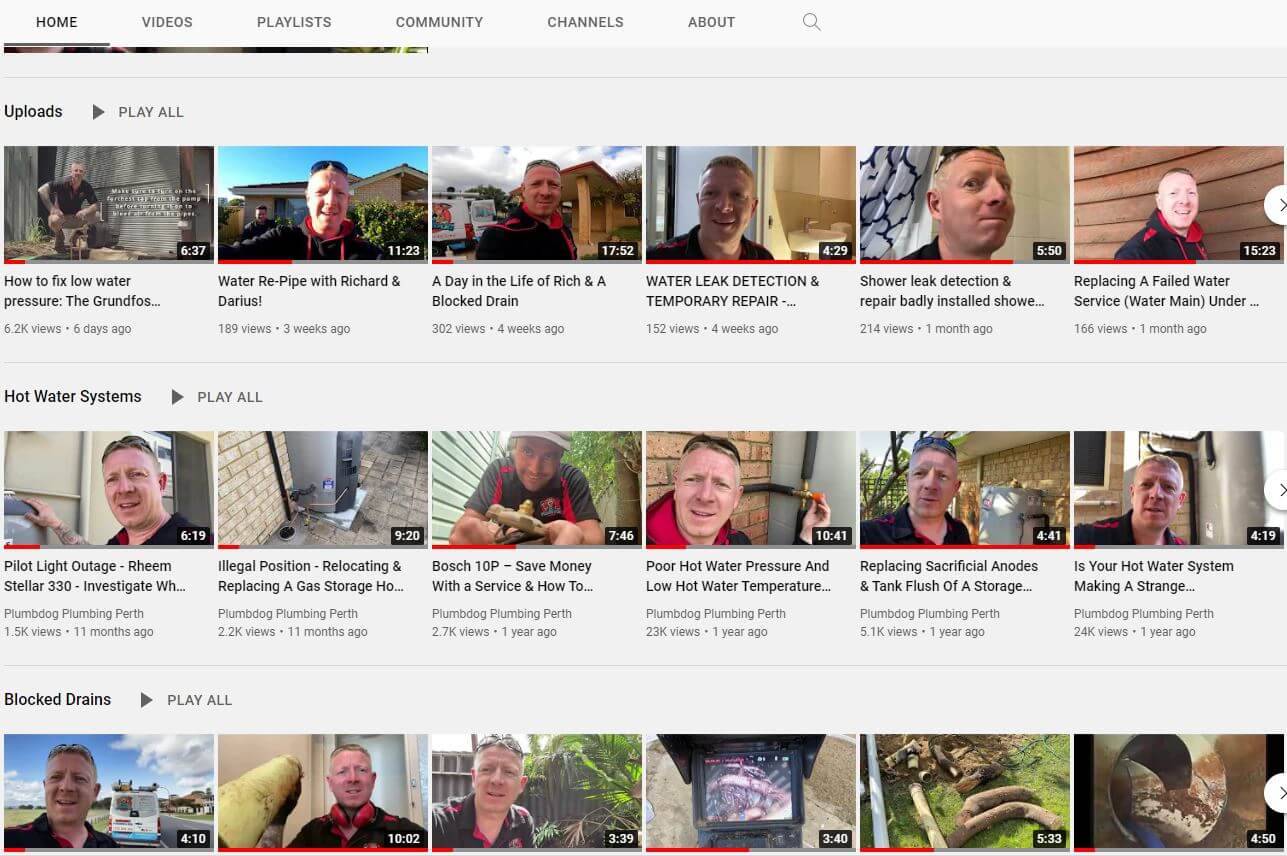

- Check out more of our VLOGs & don’t forget to like and subscribe to our YouTube channel!

Plumbdog Leak Detection & Repairs – How We Do It

Do you hear running water on your property, but as far you remember you don’t have a fountain or pond in your home? This video will show how Richard will track and fix a burst water pipe. Unlike many others, we will find the leak and we will fix the problem too without having to call on or recommend anyone else to get the whole job done.

Sniffing Out The Problem

To give a bit of a background, we received a call from a client that there’s a leak in his property. He was able to identify the area where the sound of the running water came from and it is somewhere in the laundry and bathroom. The client was also able to isolate the problem that it was the hot water line.

Effective and Efficient

Our top dog Richard starts his investigation by checking the water metre, and this confirmed that there is indeed a leak in the property. Thanks to the information that the client has provided the location was narrowed down between the bathroom and laundry area. Of course, we wouldn’t want to be digging on the entire pipeline just to find the source. Here in Plumbdog we made sure to use advanced technology to make our less time-consuming. To find the leak source accurately, Richard, turned on the hot water so that once it starts flowing down the pipes the heat will be detected by our equipment. He used our thermal imaging infrared scanner, the gear can sense heat, which will make searching easier. He walked around the perimeter of the laundry and bathroom and saw a significant amount of heat near the drain.

Gotcha!

He removed a few blocks and started digging in the area that the scanner had identified where the leak may be coming from. Almost two feet below he sees a pool of water, and lo and behold, he just found the leakage. There’s a pinhole on the pipe near the tee joint. All of that accomplished before he was even able to finish his morning coffee!

Resolve in One CALL

Richard proceeds to replace the damaged section by welding in a new pipe and running a test after. He also checks the water metre again to make sure that the leak was just in that one spot. Seeing everything looked good, he covers the hole and do a little sweeping and make it look like nothing happened there. To finalise the service, Richard, will complete and submit a water leak loss report on behalf of the client to the Water Corporation. They will compute the credit that can be applied to the client’s water bill.

This is just one of the reasons why we say we have ‘all the gear and every idea’. We are maintenance plumbing specialists and leak detection and repairs as well as blocked drains are just a couple of our specialties.